To obtain meaningful results, the analysis sample must fully represent the original material and the sample preparation process be carried out reproducibly. Most sample materials can be reduced to the required fineness at room temperature by choosing a mill with a suitable size reduction principle (impact, pressure, friction, shearing, cutting).

For example when even a small temperature increase affects the sample in a negative way; or when the material is very elastic and the above-mentioned grinding principles only cause deformation. The perfect solution for these types of samples is cold or cryogenic grinding.

or dry ice (-78 °C) which embrittle the sample by cooling and making it break more easily. Another advantage is the preservation of volatile components of the sample. In this article, we explain for which sample materials cryogenic grinding is applicable, which laboratory mills are suitable and which other aspects need to be taken into consideration.

are regulated by the first part of the IEC 60068 standard. The following sections look at the specific requirements of the respective applications.

Many polymers (plastics such as PP, PET, PA, etc.), as well as other materials, show visco-elastic behavior during grinding which results in plastic deformation. This means that a crack initiation - and thus a break-up - does not occur. Elastomers like silicone baking dishes or rubber tires which, due to their flexibility, are used at room temperature, have a so-called glass transition temperature far below room temperature.

If elastic-plastic samples are immersed in liquid nitrogen, their temperature falls below the glass transition temperature; this reduces the ability of the material to resist high mechanical stress by elastic-plastic behavior or viscous flow. If this pre-cooled material is then ground in a mill, the sample shows brittle-breaking behavior. Cryogenic grinding is also suitable for hard plastics even though this material is brittle at room temperature. For a successful size reduction process, the temperature of the sample must not exceed the glass transition temperature.

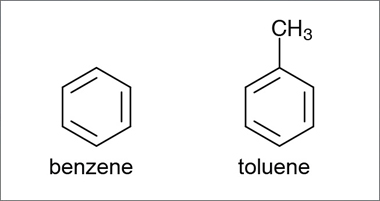

Materials with volatile components like solvents (benzene, toluene, PCB, PCP, etc.) are difficult to prepare properly for analysis because a temperature rise during grinding may lead to a loss of the analytes. The increased particle surface resulting from the grinding process further promotes the emission of volatiles. The low temperature of liquid nitrogen or dry ice substantially reduces the high vapor pressure of the components and embrittles the sample matrix. Thus the volatile components are hardly affected by the relative temperature increase which occurs during the grinding process.

If biological samples are prepared, for example for subsequent extraction of nucleic acids from yeast, bacteria, plants, or human/animal tissue, they may be highly temperature-sensitive during and after the process and may even be destroyed. In such cases, cryogenic grinding helps to improve the process by embrittling groups of cells and cell walls, making them disrupt more easily and slowing down the subsequent decomposition of the cell fragments. Undesired cell reactions are practically “frozen” by immersing the sample into LN2 so that cell activities can be observed at a later point in time.

Sticky or tough sample materials like cheese, raisins, wine gum, or marzipan simply clump together when the ground is at room temperature and are not sufficiently homogenized. The low temperature of the cryogenic process prevents the sample from clumping so that it is thoroughly homogenized and suitable for analysis.

For many materials pulverization with liquid nitrogen or dry ice is the only possible way of obtaining a sample suitable for subsequent analysis. RETSCH offers a range of laboratory mills that allow for gentle and efficient cryogenic sample preparation.

Their use considerably reduces both the cost and labor required for low-temperature grinding. A selection of suitable accessories ensures that the grinding process is carried out safely.

| SAMPLE | MIll | ACCESSORIES | FEED QUANTITY | GRINDING TIME | SPEED | FINAL FINENESS |

| Gummy bears | MM 400 | • 2 grinding jars stainless steel 50 ml • 2 grinding balls 25 mm stainless steel • CryoKit, liquid nitrogen |

10 pieces | 1 min | 30 Hz | < 300 µm |

| Caoutchouc | CryoMill | • Grinding jar stainless steel 50 ml • Grinding ball 25 mm stainless steel • Liquid nitrogen |

4 g | 2 min | 30 Hz | < 500 µm |

| E. coli bacteria | CryoMill | • Grinding jar stainless steel 50 ml • Grinding ball 25 mm stainless steel • Liquid nitrogen |

10 ml frozen cell pellets | 2 min | 30 Hz | complete cell disruption |

| Plastic granulate | ZM 200 | • 12-tooth push fit rotor • Distance sieve 0.5 mm • Cyclone • Liquid nitrogen |

40 g | 20 s | 18,000 min-1 | < 500 µm |

| Refuse-derived fuels | ZM 200 | • 12-tooth push fit rotor • Distance sieve 0.75 mm • Cyclone • 300 g dry ice |

150 g | 30 s | 18,000 min-1 | < 0.75 mm |

| Wine gum | GM 300 | • Grinding container stainless steel • Full metal knife • Cryo lid with aperture • Dry ice |

500 g | 40 s and 20 s | 1000 min-1 und 4000 min-1 | < 0.8 mm |

| Rubber duck | SM 300 | • Parallel section rotor • 2 mm bottom sieve • Liquid nitrogen |

5 pieces | 40 s | 3000 min-1 | < 2 mm |

| Pills with liquid filling | RM 200 | • Mortar and pestle stainless steel • Liquid nitrogen |

40 pieces | 3 min | 100 min-1 | < 250 µm |

| Mill | Feed size 1 2 | Max. feed quantity 1 2 |

Final fineness 1 2 | Remark |

| Cryomill | < 8 mm | 1 x 20 ml | 50 µm | • Continuous grinding under cryogenic conditions • User comes at no point into contact with LN2 • Zirconium oxide grinding jar available for cryogenic applications |

| MM 400 | < 8 mm | 2 x 20 ml | 100 µm | • Sample is placed in leak-free grinding jar of steel or PTFE and embrittled before grinding • Intermediate cooling may be necessary |

| ZM 200 | < 10 mm | 4000 ml | 300 µm | • Embrittlement with LN2, e. g. of samples with glass transition temperature <-80°C • Dry ice is best suited for materials with low thermal capacity • Dry ice is preferably used for samples with a particle size <1 mm • Use of cyclone is mandatory |

| GM 300 | < 40 mm | 2000 ml | 500 µm | • Dry ice is best suited for materials with low thermal capacity • Dry ice cools the sample during grinding • Full metal knife used together with stainless steel grinding container and a special cryo lid |

| SM 300 | < 80 mm | 4000 ml | 2000 µm | • Cryogenic grinding only with 6-disc rotor and cyclone • Bottom sieves 2 – 20 mm suitable for cryogenic applications |

| RM 200 | < 8 mm | < 190 ml | 10 µm | • Dry ice or LN2 can be added during grinding • Only use mortar and pestle made of stainless steel |

Source article from our partners