This customized conveyor oven was designed for a manufacturer within the aviation industry. In order to meet the customer’s needs, this oven was specially designed to include unique switches for the production of new airplanes. The oven was engineered to have a long dwell time, adjustable for a slow rate. The applications within this customized oven require heat curing.

Heat curing is performed as part of the larger process of polymerization on a molecular level, but may also involve physical changes such as evaporation and condensation that increase an adhesive’s bonding properties. Some curing processes require specific temperature and humidity levels whereas others require a certain pressure. Heat cured coatings are often highly resistant to aggressive chemical substances and extreme conditions. In this case, a conveyor oven is the best equipment for this customer’s production requirements.

Heat curing is just one process that a Grieve oven or furnace can perform for your application. Our equipment can be custom designed to meet your heat treat needs and specifications, delivering consistent results because of our attention to detail and thorough testing standards.

These ovens produce heated air that is provided from full coverage supply duct work at each side of the workspace and sweeps upward through the load to a return duct at the top of the work space. Ideal for large parts placed directly on oven floor or loaded on a truck. Rear heat chamber for easy handling, low profile equipment. MAX OPERATING TEMP: 800 ºF MAX WORKSPACE (WxDxH): 96" x 144" x 96"

These ovens produce heated air that is provided from full coverage supply ductwork at each side of the workspace and sweeps upward through the load to a return duct at the top of the workspace. Ideal for large parts placed directly on oven floor or loaded on a truck. Available with removable top-mounted heat chamber, fully assembled to oven and tested. Heat chamber match marked and removed for shipping or installation clearance.

For annealing, sintering, precipitation hardening, burn-off, or any other high-temperature processing of large or numerous parts. Constructed with an isolated inner oven to eliminate heat transfer and leakage at seams commonly found in standard panel construction. Designed and constructed for long, hard, continuous use with the temperature uniformity required for consistent results at elevated temperatures.

Get a quote

Designed to allow loading and unloading of a single part at the same location. They are ideal for heating smaller parts at a workstation where a heated part is required repetitively. As an operator removes a hot part, a cold part is loaded for heating. Our extensive experience working closely with our customers ensures we can design a rotary hearth oven for your process.

MAX OPERATING TEMP: 1200 ºF

Get a quote

Vertical Conveyor Ovens are designed to minimize the use of factory floor space. They utilize vertically moving trays and are ideal for heating or curing parts within a work cell. Heated parts are periodically removed from a tray and the tray is filled with cold parts to pass through the oven. Trays can be indexed or move continuously. Our extensive experience working closely with our customers allows us to determine if a vertical conveyor is the correct solution for your heating process. MAX OPERATING TEMP: 850 ºF

MAX OPERATING TEMP: 850 ºF

Get a quote

Tunnel ovens are designed for use with the customer’s conveyor system. Our experienced engineers will collect the features of your conveyor system and develop a tunnel oven to support your conveyor as well as meet your particular heat processing requirements. Units can be provided in sections for easy installation and mating with the existing conveyor system.

MAX OPERATING TEMP: 1200 ºF

Get a quote

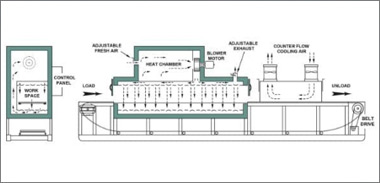

Designed and manufactured based on the customer’s specific heat process. Our experienced engineers will work closely with you to develop a Belt Conveyor oven to meet your particular requirements for part transport and heating. Oven design can include multiple heat zones, extended loading/unloading zones, special belt construction, and cooling zones.

MAX OPERATING TEMP: 1200 ºF

Get a quote

Custom ovens and furnaces can be built by Grieve to every client's specific requirements. If you don’t see the ideal oven in our catalog and “off the shelf” won’t work for you, we’ve got you covered. We can design custom industrial ovens and furnaces to your specifications.