The list of products that are subjected to some of the harshest environmental conditions during their service life is endless. For decades now, industry and research have been focusing on using dynamic climate chambers for environmental simulation. With technical opportunities increasing, the requirements of measuring technology have also changed, which has resulted in numerous standards and guidelines.

Along with the technical demands, complying with standards and guidelines is a significant challenge. The following article will explain to you why you should avoid trying to save money on the quality of the technology you use in environmental simulation. A wide range of test methods is available to identify how an object or a living system interacts with the expected environmental conditions. The test parameters are set based on certain guidelines, such as the "Good Laboratory Practice", so that they correspond to the actual stress that would be applied over a longer period of time,

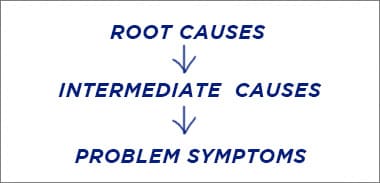

It goes without saying that measuring this test period is also an expense, which is to be taken into consideration with the acquisition of new measuring technologies. The aim of the environmental simulation is to analyze the sometimes complex network of causal chains as comprehensively as possible. Therefore, environmental simulation is mainly used to reveal causalities and to depict them as models.

Environmental simulations set high expectations on the measuring technology used and demand a high degree of expert knowledge. They are generally used to study the effects of a wide range of environmental factors on performance, function, long-term behavior, service life, and the reactions to the environment of a test object or a living system. Particularly in the field of electronics, but also in other industries such as automotive, aerospace, and medical research, environmental testing procedures are always subject to customized requirements specifications.

The general guidelines for categorizing environmental simulations are regulated by the first part of the IEC 60068 standard. The following sections look at the specific requirements of the respective applications.

Economic considerations also play an important role in determining standardized test conditions. Specifying an adequate testing period helps to save costs. By contrast, more comprehensive test series mostly pay off in the form of improved product quality and increased reliability. Standardized test results are absolutely essential when it comes to testing materials. This applies even more to challenging use cases, such as long-term measurements, or under constantly changing conditions.

Standardized test results are absolutely essential when it comes to testing materials. This applies even more to challenging use cases, such as long-term measurements, or under constantly changing conditions. Dynamic climate chambers are suitable for an extremely wide range of applications, giving them a level of universality that standard heating chambers can simply not compete with. The following areas of material testing are among the tasks that can be tackled with the help of this measuring technology:

• Aging tests

• Stress tests

• Environmental simulation

Requirements for the materials in use don’t get much higher than those within the automotive industry, with every screw, cable, hose, and the connection is subject to rigorous testing. The responsibility for material testing lies largely or at least increasingly with the suppliers – predominantly medium-sized companies of all different types. The choice as to which dynamic climate chamber is used to test subcomponents will depend on the size of the objects to be tested as well as the data required, which might include temperature, humidity, and rate of change.

Many manufacturers will opt for the deepest possible test chamber but in actual fact, that won’t always necessarily be the most beneficial solution from a practical point of view. Experience shows that wide dynamic climate chambers are the preferable option for testing hoses, cables, and certain fittings parts, for example. There is also then the option of technical upgrades to have additional access ports added. A viewing window ideally affords the opportunity of performing a visual test while the overall testing is ongoing. Are there any cracks? Discolorations? Detachments? Leaks? If there is no viewing window, it’s difficult to determine at which point the problem with the material began and which parameters it was the result of later down the line.

The fully automated simulation of external environmental conditions is the perfect example to use to consider all of the key factors at play when buying a dynamic climate chamber. Alongside the technical requirements, such as the temperature range and humidity regulation, measurement precision is one of the main crucial factors. If you want a guarantee of this, you should consider one factor that is often underestimated: homogeneous temperature distribution when fully loaded. Operation not being intuitive can also lead to test results being incorrect, so you should always ensure that a dynamic climate chamber is practical to use before you buy it.

As you might well imagine, the higher the temperature range rating of a dynamic climate chamber, the wider the range of applications it will be suitable for.

Temperature range for MK and MKF: -40°C to 180°C

Temperature range for MKT & MKFT: -70°C to 180°C Standard models usually manage to reach a high-temperature range with corresponding heating up and cooling down periods. But a high-temperature range is not enough on its own to meet all the requirements of modern testing procedures.

The following questions should help you assess the performance of a dynamic climate chamber in terms of temperature:

• How is the temperature accuracy guaranteed?

• Is there a safety device to prevent overheating?

• Is the unit also designed for cyclical temperature tests?

• How exactly is the temperature displayed?

Environmental simulation chambers from BINDER have been developed specifically for cyclical temperature tests and they boast impressively high-temperature accuracy and reproducible results. The simulation of natural temperature fluctuations using preheating chamber technology is unique within the industry.

The simulation of environmental conditions in particular usually takes place over very long periods of time. In this case, humidity regulation is hugely significant if the quality of the measured data is to be assured. Test scenarios within extreme climatic ranges with a high humidity level place huge demands on the technical capability of standard dynamic climate chambers. Plus, there has to be the option of controlling climate values that shift frequently with set tolerances. If cyclical environmental simulations are something else you need from your dynamic climate chamber, make sure you consider the following questions:

• How is the water supply guaranteed?

• Is humidity generated in the interior (usable space) or on the outside?

With environmental simulation chambers from BINDER, the water supply is provided independently of location via a storage tank. Humidity is regulated using a capacitive humidity sensor and steam humidification. There is also a condensation protection system you can program to further guarantee the quality of your measured data.

Special dynamic climate chambers also allow for moisture to be removed at ambient temperature. This kind of process is particularly important when it comes to testing and storing electronic components. Stress tests, on the other hand, involve even the most sensitive technology being pushed to its limits.

The corresponding conditions can be recreated in the dynamic climate chamber – ideally during operation. A dynamic climate chamber requires an access port for the unit’s power supply and, of course, a viewing window to allow for electronic systems to be tested in full.

The homogeneous temperature distribution is crucial – above all when the test chamber is fully loaded but also during all long-term tests in general. As having different temperature zones inside the test chamber can deliver incorrect measured values, it is important that dynamic climate chambers have technology like BINDER APT.lineTM to rule out this problem.

The average heating-up rate as per IEC 60068-3-5 [K/min] and the average cooling down rate as per IEC 60068-3-5 [K/min] are also important here. The more effective the technology installed is, the quicker it will be to set the required temperature and have it applied evenly throughout the test chamber.

Taking all of these factors into account, there is one main question to ask the manufacturer: How long are the heating up and cooling downtimes, and how are they regulated?

The only way to guarantee maximum measurement precision is to have all of the components installed in a dynamic climate chamber working together. The main feature you want from the technology is for measurements to be reproducible. It’s not just a case of recording all of the test parameters – they also need to be logged ready to be repeated.

Dynamic climate chambers will ideally come with an Ethernet interface to allow for all of the measured data to be accessed via your company’s own testing software.

If you need to assess a dynamic climate chamber’s measurement precision, you will need to pay attention first and foremost to the way in which all of the components installed work together.

• Are temperature and humidity both regulated effectively?

• What are the potential risks associated with the operation?

• Which safety devices are installed?

• Which interfaces are available for accessing data?

Alongside the technical aspects, it’s also important that your unit is practical and easy to use. The design and interface should be as functional as possible, especially given that incorrect test results can be delivered when measurement units aren’t used properly. Elements of a practical design include ease of access and cleaning of the interior. It should also be easy to move the unit so you have the option of placing it in a different position temporarily while long-term measurements are being performed, for example.

One feature that really sets BINDER dynamic climate chambers apart is the comparatively wide access point, making it much easier to test large objects. Units from BINDER also come with an access port as standard for special applications, such as those that require a separate power supply in the interior. Further access ports can be added to create compatibility with other applications, including testing tensile forces.

The built-in interface and software supplied should be as intuitive as possible to use. Units that don’t have digital interfaces and dedicated software have not been able to keep up with the requirements for some time now. It is possible to move the unit and change where it is positioned without having to use a lifting carriage.

The following questions should help you to assess the design and operation:

• Can the unit be moved and loaded with ease?

• Is it easy to clean?

• Which safety devices does the unit come with?

• What is the interface like? Is it easy to use?

• Are there digital interfaces?

Special requirements call for sophisticated technology. The specifications of environmental simulation chambers from BINDER are truly impressive – especially if you need to test materials under extreme or highly realistic environmental conditions in line with specific standards. The effective regulation of the temperature and humidity ensures that measurement results are highly accurate – no matter what the conditions are.

With dynamic climate chambers from BINDER, you have a tool for standardized testing of your materials and components that comes with plenty of standard equipment and ease of access. BINDER units have proven to be reliable in practical applications within a wide range of industries over the decades. As one of the leading suppliers of simulation chambers, you can rely on us to offer you comprehensive service and support, short delivery times, and the best possible price for our units.

The level of measurement precision offered by environmental simulation chambers from BINDER is an unprecedented quality advantage within the industry. Not to mention that they come with an Ethernet interface too. The controller with time-segment programming means it is straightforward to set all of the necessary parameters and the programming options are extensive.

Load tests of vehicle components

• Test procedures in accordance with test standards

• Resistance to aging and lifetime of painted and coated parts

• Determination of durability, peeling, crack formation, and changes to the degree of color and gloss

• Heat aging to test temperature resistance

• Optimal process reliability

• Precision and reliability

• Location: laboratory of Lothar Bix GmbH

Searing heat, Siberian cold, tropical humidity, or simply just wind and rain – most vehicle components come into contact with a wide range of environmental influences throughout their lifetime that impair their function and/ or appearance and therefore cut short their operating life. During daily use, they are also frequently exposed to severe mechanical loads and have to be able to function safely and reliably even under extreme conditions. The various vehicle parts and materials are therefore subjected to demanding load tests to determine their resistance to climatic influences and temperature.

For automotive suppliers, the ever-increasing requirements and warranty periods represent a real challenge. What’s more, many companies have established their own test standards. Automotive manufacturers of painted and coated components have also developed a whole host of special test procedures. Nearly all plastic parts inside the vehicle are now painted. Testing the durability of paint finishes Lothar Bix GmbH from Meßkirch specializes in innovative coating methods and high-quality paint finishes. In order to test the durability and resilience of paint finishes or coatings, the company performs an extremely wide range of environmental simulation tests in its in-house test laboratory for customers from the automotive industry.

The tests are run in accordance with OEM regulations and international standards such as VW TL 226 and Daimler DBL 7384. In constant climate chambers and drying chambers from BINDER, the painted or coated parts are tested in terms of various criteria: temperature and weather resistance, a lifetime in various temperature ranges and climatic zones, as well as resistance to aging. Interactions with various media, such as sweat, sun cream, or care and cleaning products, are also determined.

BINDER drying chambers from the ED series are used for heat aging and to test temperature resistance. The units have a wide temperature range from 5°C above ambient temperature to 300°C. Based on the high temperatures, the behavior of the test parts can be determined with respect to durability, peeling, crack formation, and changes to the degree of color and gloss.

In dynamic climate chambers from the MKF series, the painted and coated parts are tested under dynamic conditions. Complex dynamic climate profiles are run with a temperature range of -40°C to 120°C, a humidity range of 10% RH to 98% RH, and a storage period of up to 30 days.

Cyclical alternating climate tests or even accelerated short-term tests involving time-lapse are used to determine the lifetime of the test specimens at 90°C / 96% RH over 3 to 7 days, and their resistance to aging under fluctuating environmental influences is characterized. The temperatures and duration of a climate test are adapted to the conditions under which the product is used and its life expectancy.

BINDER drying chambers from the ED series are used for heat aging and to test temperature resistance. The units have a wide temperature range from 5°C above ambient temperature to 300°C. Based on the high temperatures, the behavior of the test parts can be determined with respect to durability, peeling, crack formation, and changes to the degree of color and gloss.

Wolfgang Scherer, Head of Quality Assurance / QMO at Bix, explains why the company opted for simulation chambers from BINDER. The large interior with a volume of over 720 liters is perfect for us to also test complete components.