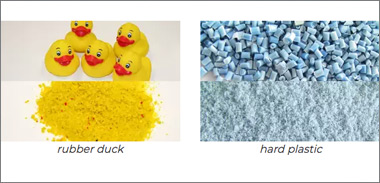

A laboratory ball mill is an indispensable tool when it comes to the rapid, reproducible pulverizing, milling, or grinding of a large variety of materials. Depending on the configuration and choice of the mill, samples can be soft, elastic or fibrous but also hard or brittle.

RETSCH mixer mills are true all-rounders. They homogenize, for example, alloys, animal feed, bones, ceramics, cereals, chemical products, coal, coke, drugs, electronic scrap, glass, grains, hair, minerals, oil seeds, ores, paper, plant materials, plastics, sewage sludge, soils, straw, tablets, textiles, tissue, tobacco, waste samples, wood, wool, etc.

Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times.

In a drum mill, the sample (usually pre-crushed material) is placed inside the drum with the grinding balls and subjected to external forces.

The Ball Mill is used for fine grinding of solid matter by impact and friction in dry conditions. The drum, which contains the sample and grinding balls, rotates around a horizontal axis. Whereas particles break more easily when larger grinding ball diameters are used, smaller diameters lead to a substantially higher final fineness.

Application examples

alloys, bentonite, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, charcoal, chemical products, clay minerals, coal, coke, compost, concrete, electronic scrap, fibres, glass, gypsum, hair, hydroxyapatite, iron ore, kaolin, limestone, metal oxides, minerals, ores, paints and lacquers, paper, pigments, plant materials, polymers, quartz, seeds, semi-precious stones, sewage sludge, slag, soils, tissue, tobacco, waste samples, wood, ...

The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time - with only minor warming effects. These ball mills are also suitable for mechanochemistry.

Application examples

alloys, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, chemical products, clay minerals, coal, coke, concrete, fibres, glass, gypsum, iron ore, kaolin, limestone, metal oxides, minerals, ores, paper, pigments, plant materials, polymers, quartz, semi-precious stones, sewage sludge, slag, soils, tea, tobacco, waste samples, wood, & more.

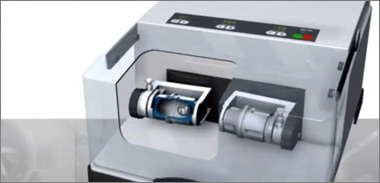

Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery.

The grinding jars of the mixer mill ( ex. - MM 500 Nano) perform radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the grinding jars and pulverize it. Also, the movement of the grinding jars combined with the movement of the balls result in the intensive mixing of the sample. The degree of mixing can be increased even further by using several smaller balls.

Application examples

Alloys, animal feed, bones, ceramics, cereals, chemical products, coal, coke, drugs, glass, grains, hair, minerals, oil seeds, ores, paper, plant materials, sewage sludge, soils, straw, tablets, textiles, tissue, tobacco, waste samples, wood, wool & more.

Cryogenic grinding is a process where thermally sensitive and elastic substances are successfully processed by cooling with liquid nitrogen. The CryoMill is a laboratory ball mill specifically designed for this application. It features an integrated cooling system that continually cools the grinding jar with liquid nitrogen before and during the grinding process. Thus, the sample is embrittled and volatile components are preserved.

The liquid nitrogen is continually supplied from an autofill system in the exact amount required to keep the temperature at –196 °C. The user never comes into direct contact with LN2 which ensures a high degree of operational safety. The CryoMill's versatility (cryogenic, but also wet and dry grinding at room temperature) makes it the ideal grinder for sample quantities up to 20 ml. Powerful impact ball milling results in the highest grinding efficiency.

The CryoMill is equipped with one grinding station for screw-top grinding jars with volumes of 10 ml, 25 ml, 35 ml or 50 ml. It is also possible to use adapters for 4 grinding jars of 5 ml each as well as for 6 reaction vials of 2 ml each. A 25 ml grinding jar of zirconium oxide and matching grinding balls as well as a PTFE jar are available for applications where steel would cause sample contamination.

Due to the automatic embrittlement of the samples during cryogenic grinding the CryoMill is suitable for pulverizing, for example, waste, soil, chemical products, tissue, hair, wood, sewage sludge, bones, plastics, oilseed, paper, plants, pills, textiles, animal feed, wool etc.

Powerful cryogenic grinding by impact and friction with up to 30 Hz 3 different grinding modes (cryogenic, dry/wet at ambient temperature) closed LN2-system (Autofill) for enhanced user safety screw-top jars ensure convenient, leak-proof operation wide range of accessories including various jar and ball sizes, adapter racks and LN2 feeding system optional zirconium oxide jars specifically designed for cryogenic grinding 9 programmable cooling and grinding cycles (10 s to 99 min)

The grinding jar of the CryoMill performs radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the jar and pulverize it. The grinding jar is continually cooled with liquid nitrogen from the integrated cooling system before and during the cryogenic grinding process.

CRYOMILL - efficient cryogenic grinding at -196°C

| Applications | size reduction, mixing, homogenization, cell disruption |

| Field of application | agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | hard, medium-hard, soft, brittle, elastic, fibrous |

| Size reduction principle | impact, friction |

| Material feed size* | <= 8 mm |

| Final fineness* | ~ 5 µm |

| Batch size / feed quantity* | max. 20 ml |

| No. of grinding stations | 1 |

| Setting of vibrational frequency | digital, 5 - 30 Hz (300 - 1800 min-1) |

| Typical mean grinding time | 10 min / 4 min (cooling / grinding) |

| Dry grinding | yes |

| Wet grinding | yes |

| Cryogenic grinding | yes |

| Cell disruption with reaction vials | yes |

| Self-centering clamping device | yes |

| Type of grinding jars | screw top design |

| Material of grinding tools | hardened steel, stainless steel, zirconium oxide, PTFE |

| Grinding jar sizes | 5 ml / 10ml / 25 ml / 35 ml / 50 ml |

| Autofill | 50 l |

| Setting of grinding time | digital, 30 s - 99 min |

| Storable SOPs | 9 |

| Electrical supply data | 100-240 V, 50/60 Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | 260 W |

| W x H x D closed | 395 x 373 x 577 mm (D: 710 mm with exhaust tube) |

| Net weight | ~ 45 kg |

| Standards | CE |

*depending on feed material and instrument configuration/settings